TM 5-6115-586-34

Section II. TROUBLESHOOTING

2-3. General

a. This section provides information useful in diagnosing and correcting' unsatisfactory operation or failure of the

power plant and its components. Malfunctions which may occur are listed in table 22. Each malfunction stated is

followed by a list of probable causes of the trouble. The corrective action recommended is described opposite the

probable cause.

b. Information concerning the use of special test equipment as an aid to troubleshooting is provided in paragraph 2-

4 of this section.

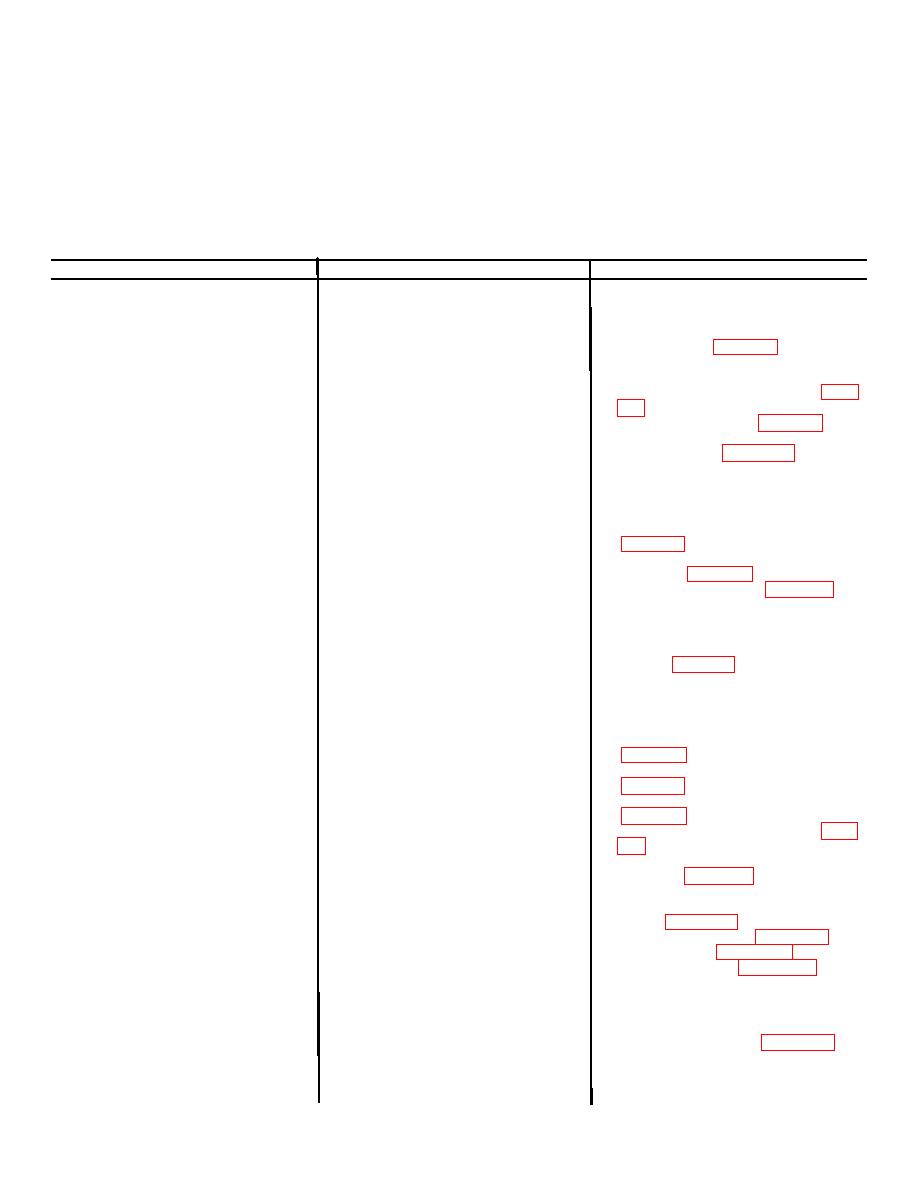

Table 2-2. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1. Fuel boost pump motor assembly

a. Defective fuel boost pump motor

a. Check that 24 VDC is present at

fails to operate (batteries

assembly.

fuel boost pump connector P35.

charged)

If 24 VDC is present, repair or

replace pump (para 4-4); if

voltage is not present, continue to

step b.

b. Defective wire harness assembly.

2. Starter motor runs but does not

Defective starter motor clutch.

Repair or replace clutch (para 3-5).

rotate engine.

3. Engine stops motoring when

No-fuel relay (K44) defective.

Replace relay K44 (para 5-33).

master switch is released from

START to RUN position.

4. Engine motors but combustion

a. Low oil or depleted fuel supply.

a. Service power plant as required.

does not occur.

(see TM 5-6115-586-12.)

b. Fuel filter clogged or defective.

b. Clean, repair, or replace fuel filters

c.

Fuel control assembly failed.

c. Repair or replace fuel control

assembly (para 3-6).

e. Oil pressure sequencing switch

e. Replace oil pressure sequencing

failed.

switch. (see TM 5-6115-586-12).

f. Fuel atomizer screen obstructed.

f. Clean or replace screen (para 3-7).

5. Engine starts but will not ac-

a. Control air lines leaking.

a. Tighten or repair control air line

celerate to governed speed or

fittings (para 3-3).

accelerates too slowly.

b. Fuel control pump assembly

b. Repair fuel control pump (para 3-

failed.

6).

c. Fuel atomizer flow divider sticking

c. Repair fuel atomizer (para 3-71.

closed.

d. Remove and clean orificed fitting

plugged.

6. Engine lacks ability to carry load.

a. Fuel filter partially clogged.

a. Replace filter elements as required

b. Control air lines leaking.

b. Tighten control air lines fittings

c.

Fuel control failed.

7. Oil leaks from vent orifice of dual

Gearbox has positive pressure

Replace pump assembly on dual pad

pad gear box.

because of pump failure.

gear box (para 3-11 through 3-

13).

8. 60 Hz frequency meter out of

Defective meter.

Test meter and if faulty, replace

limits.

meter (para 5-26).

9. DC ammeter out of limits.

Improper adjustment.

Center zero adjustment (para 5-26).

10. DC ammeter does not indicate.

a. Damaged shunt.

b. Meter open.

11. Exhaust gas temperature meter

a. Replace thermocouple (see TM 5-

does not indicate.

thermocouple.

6115-586-12).

b. Open meter.

meter. (see TM 5-6115-586-12).

12. 60 Hz ammeter does not indicate

Defective meter.

Replace 60 Hz ammeter (para 5-26).

on either leg.

13. 60 Hz ammeter does not indicate

Open current transformer.

Replace current transformer (para 5.

on one leg.

26).

2-3