TM 5-6115-586-34

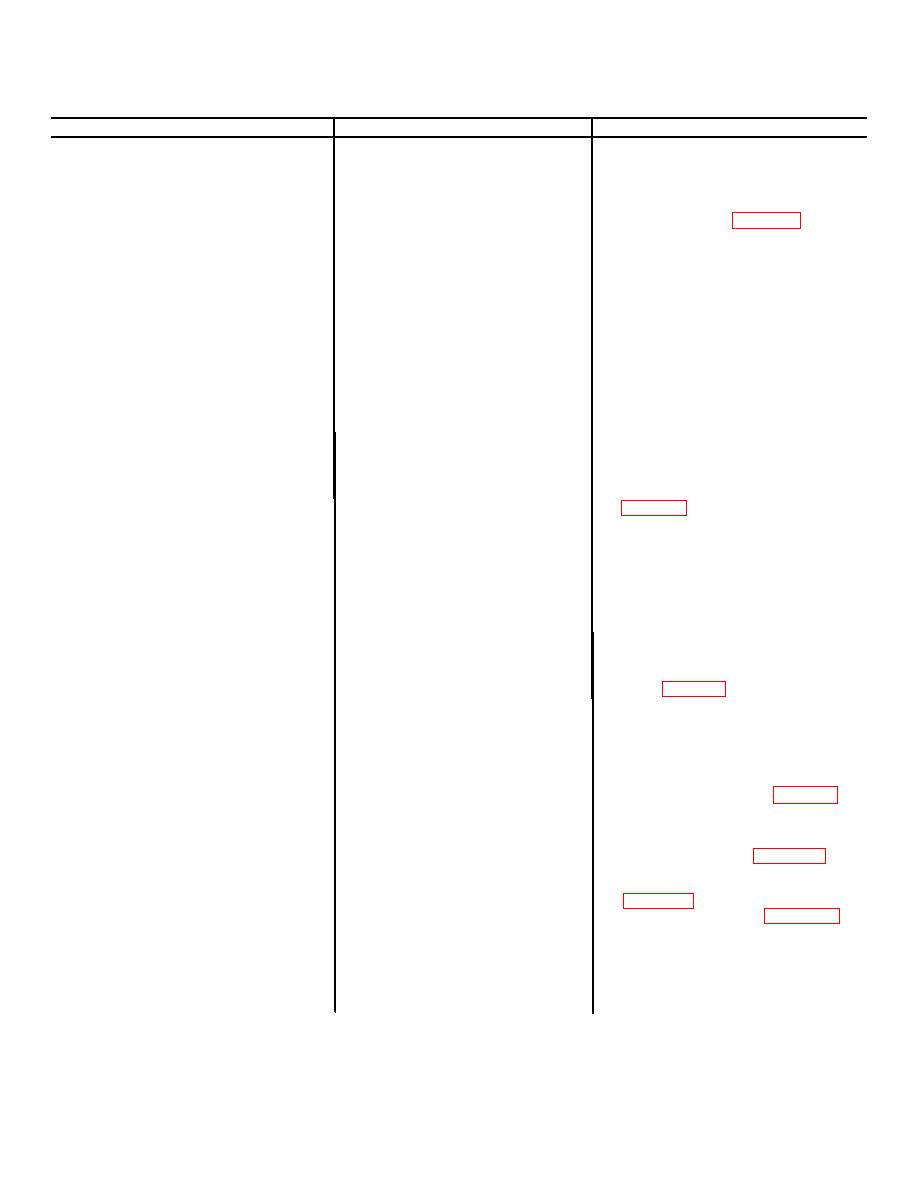

Table 2-2. Troubleshooting-Continued

Malfunction

Probable Cause

Corrective Action

25.

Refrigeration system operates but

System low on refrigerant. (Low

The refrigerant level should be above

does not meet cooling per-

refrigerant level will be indicated

the lower receiver sight glass

formance requirement. System

if the conditioned air discharge

when operating system. Check

power draw is less than normal.

(from a single part) is highly

and repair refrigerant leaks,

(Discharge conditioned air must

stratafied, i.e., top half may be at

recharge system (para 2-4b.).

be mixed for accurate tem-

near ambient temperature and a

perature measurement.)

thermal pulse is noted at the

expansion valve.)

26.

Refrigeration system operates but

a. Refrigeration, de-icing, or com- a. Compare corresponding tubing

does not meet cooling per-

pressor bypass valves are not

temperature with both systems

formance requirement. System

functioning properly.

operating and replace defective

power draw is normal.

valve (para.6-2).

b. Expansion valve defective.

b. Replace expansion valve. (see TM

5-6115-586-12.)

fan inlet.

under roof. Relocate unit or duct

exhaust gases.

27.

Refrigeration system meets

a. Refrigeration system is over-

a. Reduce refrigerant charge (para 2-

cooling performance re-

charged. (Cooling performance

4b).

quirements but has excessive

will also deteriorate with a

power draw.

Substantial overcharge, (4

pounds or more excess.)

b. Excessive compressor drag.

b. Replace defective compressor

28.

Hot or cold water pump panel

a. Pumps (B14 or B15) are seized. a. Repeat reset several times.

switches (CB11 or CB12) trip

Rotation may be imparied by

and will not hold reset. (Voltage

deposits in pump. Free or replace

to pumps is satisfactory.

pumps (B14 or B15). (see TM 5-

6115-586-12.)

b. Pump motor failed.

b. Replace pumps (B14 or B15). (see

TM 5-6115-586-12).

29.

Cold water pump (B14) does not

Defective cold water pump panel

Replace pump panel switch (CB12).

have supply voltage. (Main

switch (CB12).

(see TM 5-6115-586-12.)

contactor operation satisfactory).

30.

Hot water pump (B15) does not

a. Defective low pressure water

a. Test and if faulty, replace switch

have supply voltage. (Cold water

switch (S11).

(S11) (para 8-6, 8-7).

pump operating and pressure at

b. Defective hot water pump panel

b. Replace switch (CB11).(see TM

(S11) exceeds 10 psig.)

switch (CB11).

5-6115-586-12.)

c. Defective hot water pump con-

c. Replace contactor (K15).(see TM

tactor (K15).

5-6115-586-12.)

31.

Flow control valve does not open.

a. Hot water pressure switch (S11)

a. Check for sufficient pressure to

K14 does not have supply

open.

close switch (S11). Replace

voltage.

defective switch (S11) (para 8-6,

8-7).

b. Hot water temperature switch

b. Check that water temperature is

(S12) open.

low enough for switch (S12) or

replace if defective (para 8-11).

32.

Hot water temperature is out of

a. Hot water temperature switch

a. Adjust switch (S12) (clockwise to

limits.

(S12) is not properly adjusted.

Decrease water temperature)

b. Defective hot water temperature b. Replace switch (S12) (para 8-11).

switch (S12).

c. Defective flow control valve

c. Isolate by opening main contactor

(K14).

(K10), if exhaust gases continue

to flow from water boiler exhaust

port, replace flow control valve

(K14). (see TM 5-6115-586-12).

2-4. Use of Special Troubleshooting Equipment

a. Gas Turbine Engine Analyzer. The gas turbine engine analyzer provides electrical, hydraulic and pneumatic test

systems with their associated controls and instruments for functional testing of the gas turbine engine and malfunctioning

components. A portable multimeter and a portable fuel pressure gauge are provided for use in

2-5