TM 5-6115-586-34

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORTMAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

2-1. Special Tools and Equipment

The special tools and equipment required to perform direct support and general support maintenance on the power plant

are listed in table 2-1 below and in the Maintenance Allocation chart, Appendix B of TM 5-6115-586-12. Paragraph

references and illustrations indicating the use of special tools and equipment are listed in table 2-1.

2-2. Maintenance Repair Parts.

Repair parts, special tools, test and support equipment are listed and illustrated in TM, 5-6115586-34P.

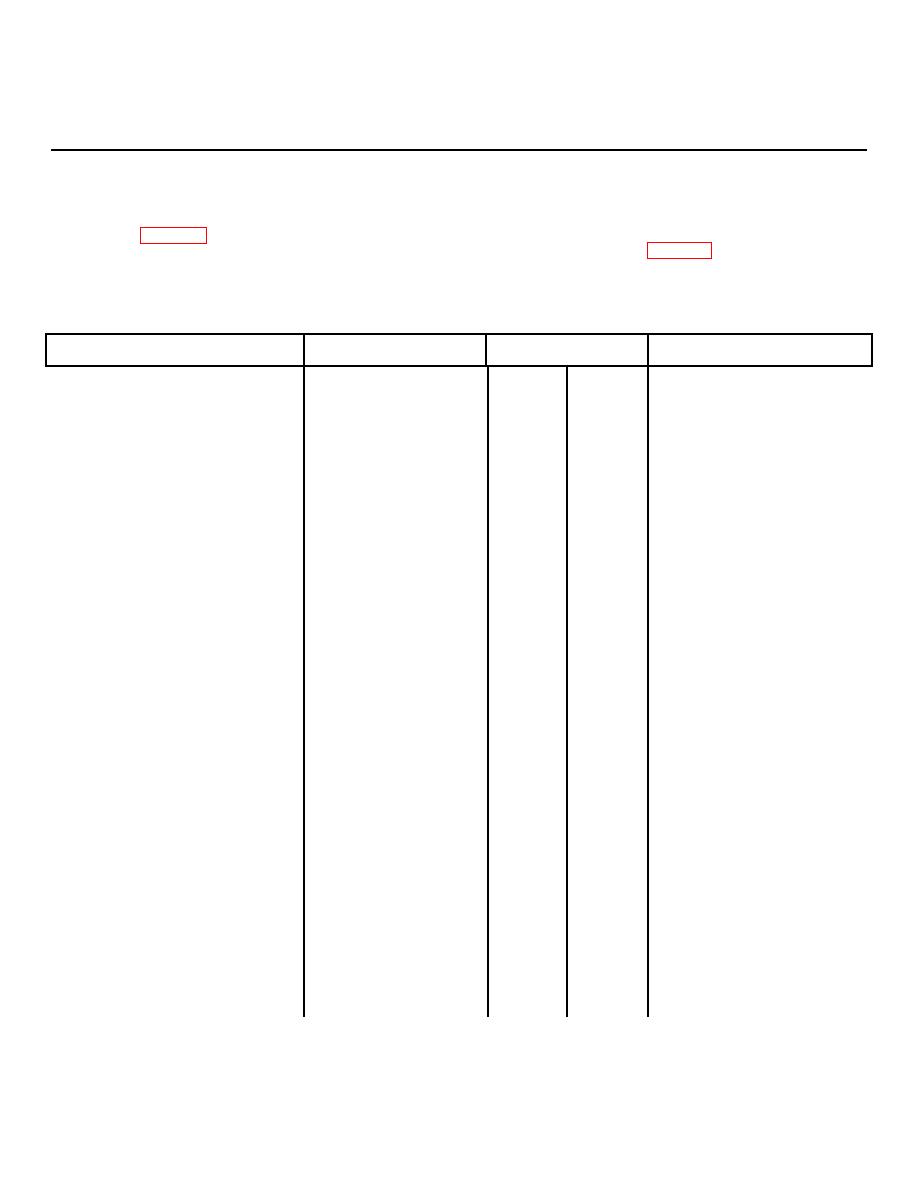

Table 2-1. Special Tools and Equipment

Item

FSN or

References

Use

part number

Stand, portable, gas turbine engine

4910-758-6189

2-12b

Support gas turbine during assembly,

disassembly, and functional testing.

Analyzer, engine, gas turbine

4920-778-6091

2-4a

Monitor operation of the gas turbine

engine.

Cable assembly, special purpose, electrical,

4940-182-4499

2-4a

Connect analyzer to electrical harness of

branched

the gas turbine engine.

Wrench, spanner

5120-793-0701

3-17,3-19

Removal and installation of accessory

output shaft nut.

Adapter, wrench

5120-608-6794

3-17,3-19

Hold output shaft during removal or

installation of output shaft nut.

Sling, beam type, adjustable

1730-115-3189

2-12b

Lifting gas turbine unit.

Mount, gas turbine engine

1730-015-8005

2-12b

Adapt one side mount of the gas turbine

unit to the maintenance stand.

Mount, gas turbine engine

1730-015-8002

2-12b

Adapt one side mount of the gas turbine

unit to the maintenance stand.

Adapter, maintenance stand

4920-118-0346

2-12b

Support accessory end of gas turbine

unit in maintenance stand.

Dolly set, utility package, transporting

285186-1-1 (99193)

Transport power plant to and from

various locations.

Wrench, spanner

5120-320-9613

3-23,3-25

Removal or installation of tailpipe.

Driver, seal

5120-525-8557

3-17,3-19

Installation of output shaft seal in

retainer.

Driver, seal

5120-733-7113

3-17,3-19

Installation of oil pump drive shaft seal in

accessory case.

Puller, mechanical seal

5120-608-8239

3-17,3-19

Removal of oil pump drive shaft seal.

Screwdriver and wrench assembly

5120-668-6122

3-6

Adjusting fuel control unit.

Adapter, fuel atomizer

4920-924-1196

3-7e

Adapt fuel atomizer to tester during

testing.

Service kit, refrigeration

4130-400-2150

2-1 thru

2-4b, 6-5b,

Service and check refrigeration system.

2-4

6-6b, 6-7e

Fixture, end play measuring

905128-1-1 (99193)

6-14,6-22

6-8d, 6-9d

Measure end play in armature of motor

driven fan.

Wrench, torque, holding fixture

5120-178-0057

6-8

6-8

Hold impeller of motor-driven fan while

impeller shaft nut is tightened.

Fixture, bearing press

272166 (99193)

6-13,6-21

6-8,6-9

Holds and aligns fan rotor shaft while

pressing bearing onto shaft.

Wrench, torque, holding fixture

5120-178-0070

6-16

6-9

Hold motor-driven fan shaft while

tightening shaft nut.

Holder, clutch torquing

4920-336-0648

3-7

3-5f

Adjustment of starter clutch torque.

Adapter, torque wrench

5120-608-4756

3-7

3-5f

Adjustment of starter clutch torque.

Plate, end seal

268129(99193)

6-3

6-5

Seal inlet ports of refrigerant condenser

during leakage tests.

2-1