KEY to figure 6-15.

(3) Remove screws (6) and washers (7); then

1. Screw

16.

End bell

remove end bell

16) with thermal protector (15)

2. Plate

17.

Clamp

attached. Unsolder wires from thermal protector; then

3. Plate

18.

Grommet

remove thermal protector from end bell.

Do not

4. Label

19.

Nut

disassemble end bell (16).

5. Connector

20.

Washer

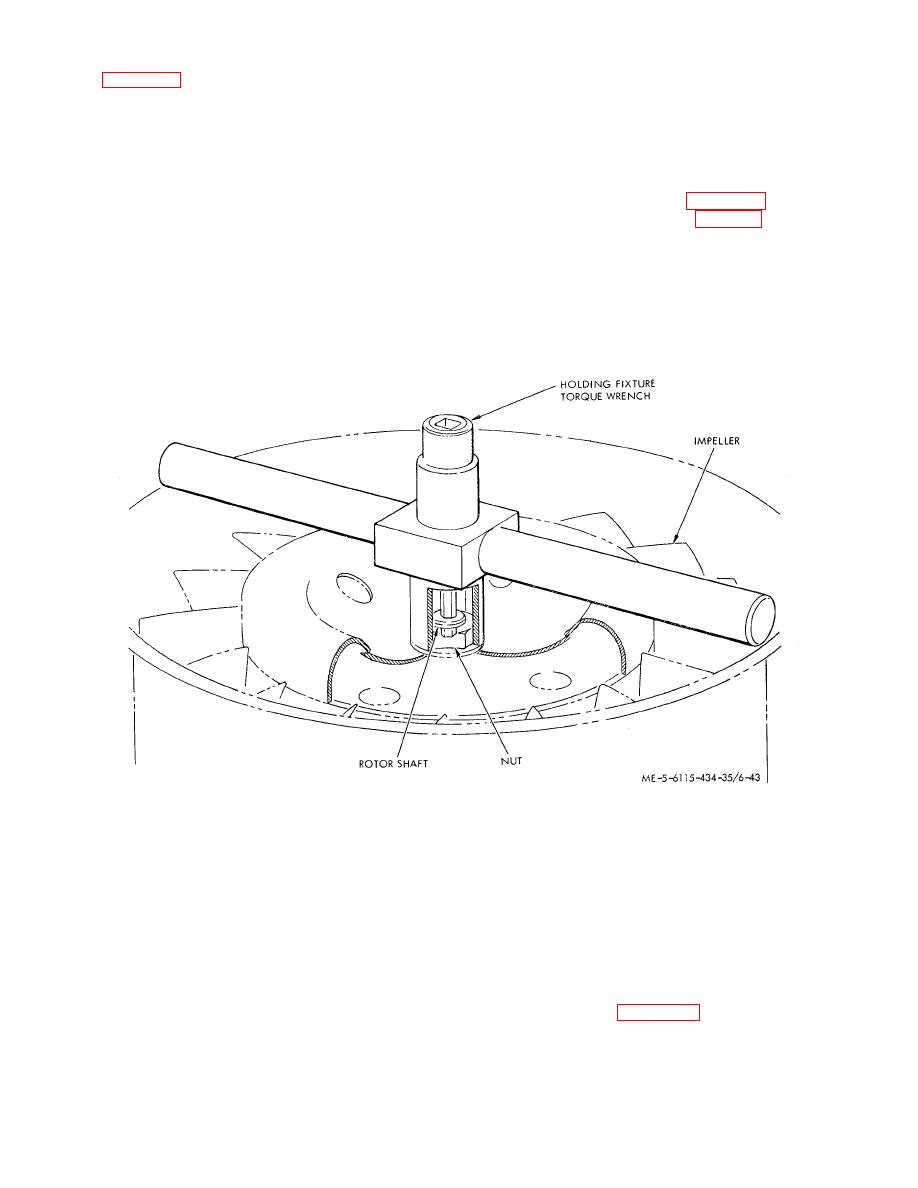

(4) Remove nut (19), using holding fixture

6. Screw

21.

Fairing

torque wrench as illustrated in figure 6-16.

7. Washer

22.

Impeller

(5) Remove rotor (24, fig. 6-15) with bearings

8. Disc

23.

Bearing

(23).

9. Disc

24.

Rotor

(6) Do not remove stator (27) from housing

10. Disc

25.

Housing assy

(30).

11. Washer

26.

Set screw

12. Nut

27.

Stator

13. Washer

28. Retainer

14. Screw

29. Insert

15. Protector, thermal 30. Housing

Figure 6-16. Holding fixture torque wrench.

c. Cleaning, Inspection and Repair.

(a) Inspect all parts and wiring for damage.

(1) Cleaning.

Check bearing surfaces; bearing surfaces must have

no discoloration, indicative of overheating.

(a) Clean thermal protector (15), motor rotor

(b) Inspect all threaded parts for stripping or

(24), and motor-stator (27) in fan housing (30), using a

cross-threading.

soft bristle brush.

(c) Inspect plates (2,3) and label (4) for

Warning Varnish on stator (27) is soluble in solvent. Do

not allow solvent to contact stator. Use solvent in well

legibility and for security of attachment.

ventilated area. Avoid breathing fumes. Keep away

(d) Inspect connector (5) for loose, bent.

from flame.

o0 broken pins and for evidence of arc-over between

(b) Clean exterior surfaces of housing (30)

pins and shell.

with a clean, lint-free cloth moistened with dry cleaning

(e) Connect thermal protector (15) to a test

solvent (Federal Specification P-D-680).

circuit as shown in figure 6-17 which monitors opening

(c) Wash all other parts in dry cleaning

and closing of the contacts. and check operation at the

solvent and dry thoroughly.

following temperatures:

(2) Inspection.

6-27