mounting flange with washers (8), bolt (7) and nuts (6).

c. Install packing (4) on nozzle (3) and install

Tighten nuts (6) and bolts (7) to torque value 75 to 85

nozzle into housing. Secure nozzle (3) using washers

inch-pounds.

(2) and bolt (1).

b. Refer to TM 5-6115-586-12 for installation

3-20. Installation

instructions for the cooling fan assembly, oil pump

assembly, centrifugal switch assembly, fuel control unit,

accessory gearcase assembly as follows:

and starter motor assembly.

(1) Install spring (12) and shaft (11) into

compressor and turbine shaft. Install packing (10) onto

accessory drive assembly.

gearcase input flange.

(2) Position gearcase assembly (9) on output

mounting flange studs. Secure gearcase to output

Section V. COMPRESSOR AND TURBINE ASSEMBLY

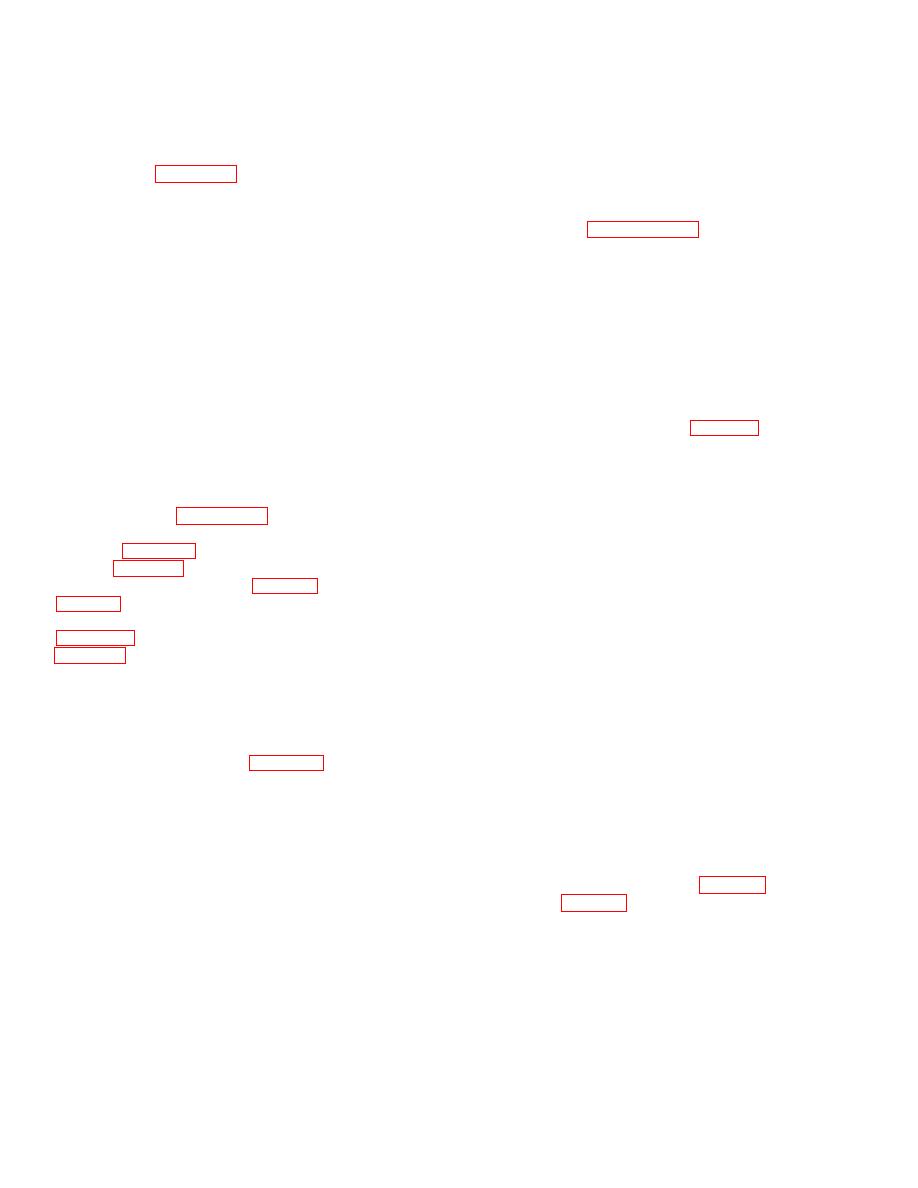

c. Remove bolts (29), washers (30), and fitting

3-21. General

(31), with packing (32) and spring (34) and packings (36,

This section contains repair instructions for the air inlet

37) installed. Remove gasket (39) and packing (33).

plenum, the turbine plenum, the combustion liner, the

d. Remove bolts (40, 41, fig. 3-12, sheet 2 of 2),

torus, the exhaust pipe, and the turbine nozzle. These

washers (42), shims (43, 44) and flange (45). Remove

components with the compressor and turbine assembly,

nuts (46), bolts (47, 48), and washers (49).

convert and direct the energy developed in the

e. Remove plenum (50) and gasket (51) and shims

combustion area to rotational mechanical energy.

(52). Using wrench (special tool; see table 21), remove

3-22. Removal

exhaust pipe (53) and gasket (54).

f. Remove nuts (55), washers (56), torus (57),

instructions regarding removal of the engine and skid

shims (58), nozzle (59) and shims (60).

assembly (para 2-11) and removal of the engine from

g. Do not disassemble the compressor and turbine

the skid (para 2-12).

assembly (61). Refer repairs to depot maintenance.

3-24. Cleaning, Inspection, and Repair

a. Cleaning. Parts may be cleaned by using an

c. Remove the dual pad accessory drive assembly

approved solvent in a dip tank or use of spray in a

positive outside ventilated spray booth.

Vapor

(para 3-16 c).

degreasing or soap cleaning solution may also be used

3-23. Disassembly

if suitable equipment is available.

Note

Warning

Tag shims as removed and keep

Fumes from spray or vapor are

them together so that they will be

toxic and shall not be inhaled.

properly installed at assembly.

Wear solvent-resistant gloves to

a. Remove clamp (13, fig. 3-12, sheet 1 of 2)

prevent absorption of solvent

screws (14) and washers (15) and remove inlet air

through

the

skin.

Fire

plenum (16).

precautions shall be observed

b. Remove bolts (17), and washers (18) and

remove atomizer (19) and packing (20). Remove bolts

and fire fighting equipment shall

(21) and washers (22) to remove igniter (23) and gasket

be available.

(24). Then remove clamp (25) and remove combustor

b. Inspection.

cap (26), packing (27) and liner (28).

(1) Inspect torus (57, fig. 3-12, sheet 2 of 2)

as follows: (fig. 3-20 and 3-21.)

3-34