TM 1-1500-204-23-8

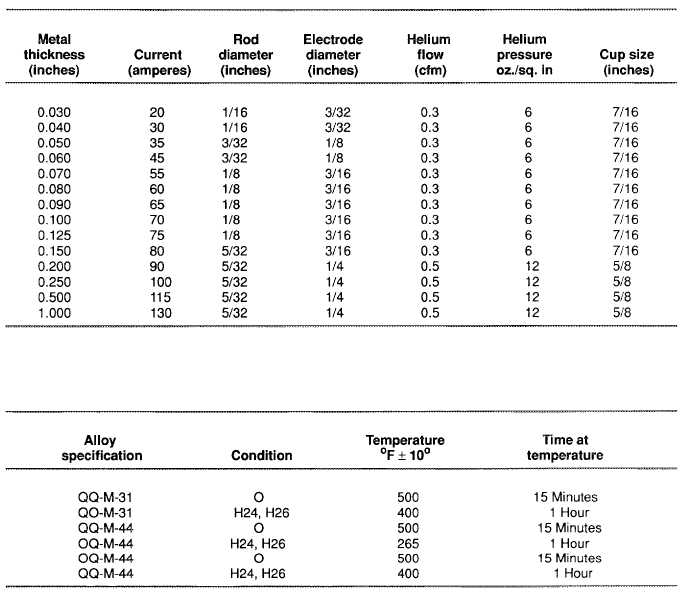

Table 3-5. Machine Settings for Arc Welding Magnesium

(1)

Cleaning. Clean electrodes frequently by

polishing with abrasive cloth, Federal Specification P-C-

451, to avoid pickup.

(2)

Machine settings. Use the settings

furnished by the manufacturer as a guide.

(3)

Spot spacing. Spacing between spot

welds should not be less than eight times sheet thickness,

with 1/4 inch minimum. Preferred spacing is 16 times

sheet thickness. Edge distance should be at least four

times sheet thickness, with 3/16 inch minimum. Preferred

distance is six times sheet thickness.

3-7. Corrosion-Resistant Steel and Nickel Chromium

Alloy Welding. The gas, arc, and spot methods may be

used for welding steels. The following paragraphs cover

distinguishing between corrosion-resistant steels and

nickel-base alloys, special welding considerations, and

procedures for gas, arc, and spot welding.

a. Distinguishing Corrosion-Resistant Steels and

Nickel-Base Alloys. The following test procedures will

enable the mechanic to identify the class of material:

3-15

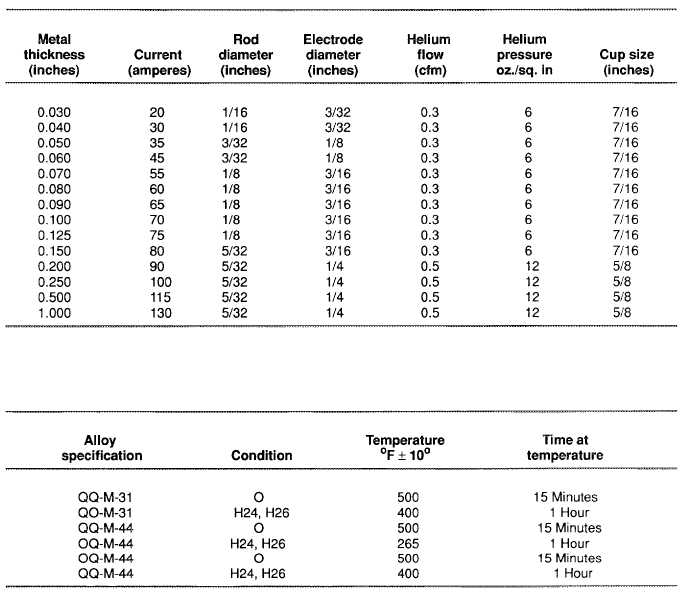

Table 3-6. Stress Relieving Treatment