with the wiring diagram (fig. 4). Make certain all

This section gives instructions on starting and stopping

connections are secure, make good contact, and have

the welding machine, basic motions of the welding

ample

clearance.

machine, and on co-ordinating the basic motions, to

(d) Attach supply ground wire to welder housing and

perform the specific tasks for which the equipment is

replace the top cover. This cover must be in place

designed. Since nearly every job presents a different

when operating the welding machine.

problem, the operator may have to vary given

(e) Check for proper direction of rotation on the initial

procedures to fit an individual job.

start as described below.

26. Starting

b. Starting.

a. Preparation for Starting.

(1) Push START button (fig. 7).

(1) Perform the necessary daily preventive

(2) On the initial start check the direction of rotation

maintenance services (para 36).

as indicated by the arrow on the name plate. If

(2) Connect welding machine to power supply as

rotation is incorrect, press STOP button, shut off

follows:

main power supply disconnect switch, and

(a) Approximate full load amperes, and

interchange any two line leads (fig. 4).

recommended fuse and power cable sizes

are listed in table 1.

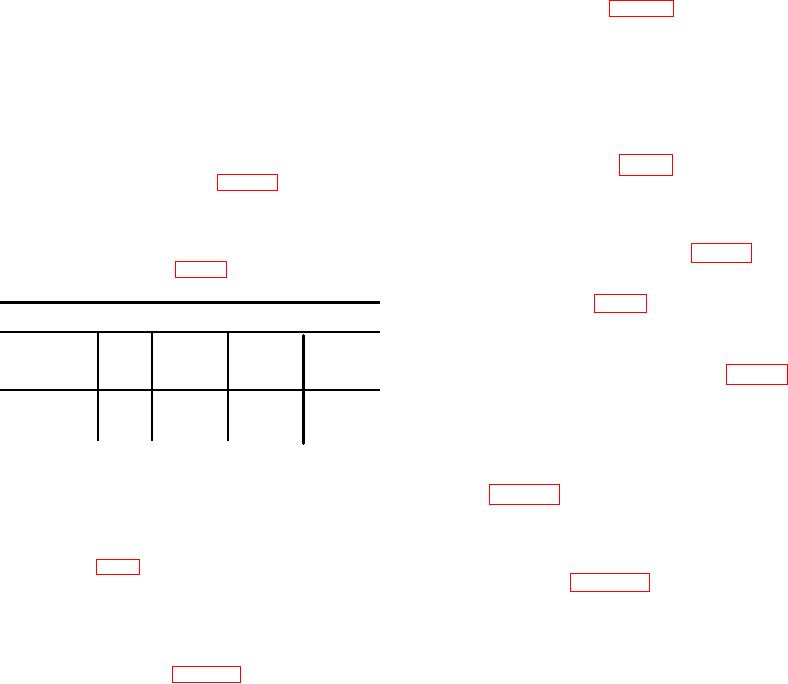

Table 1. Wiring Data

27. Stopping

Push STOP button (fig. 7) to stop welding machine

Three-phase, 60 cycle, ac

operation.

Input

Full load

Power lead

Min. Fuse

28. Operation Under Usual Conditions

Rating

voltage line amperes size B and S

size in

a. Connect electrode and ground cable (para 9).

amperes

b. Attach clamp of ground cable to work metal

making sure it is at a clean, paint and rust free spot for

300 Ampere

230

57.5

4

125

good

contact.

300 Ampere

460

28.8

8

75

c. Set reversing switch at "straight" or "reverse"

position and check the polarity of the electrode.

(b) A tag on the welding machine indicates the line

d. Set electrode selector for the size of electrode to

voltage for which the unit is connected at the

be used (para 21). If unusually high or low currents are

factory. Be sure it corresponds with the power

required for a particular electrode, it may be necessary

supply voltage to be used. If connection changes

to turn the electrode selector to the next higher or lower

are required, change motor leads and contactor

setting.

coil leads and jumpers as described in the wiring

e. Set rheostat current selector to the desired

diagram (fig. 4).

current in amperes (para 20). The remote rheostat

current selector controls the welding machine for remote

Warning: Make sure the main power supply

work.

disconnect switch is shut off before making any

Warning: Do not perform any welding operation

connections.

without a welder's helmet. The flash of the welding

arc can cause injury to the eyes.

(c) Remove the top cover (para 54), run power supply

f. The approximate current range for bare

leads through the hole in the back panel and

connect to the motor starter terminals in accordance

AGO 8244A

13