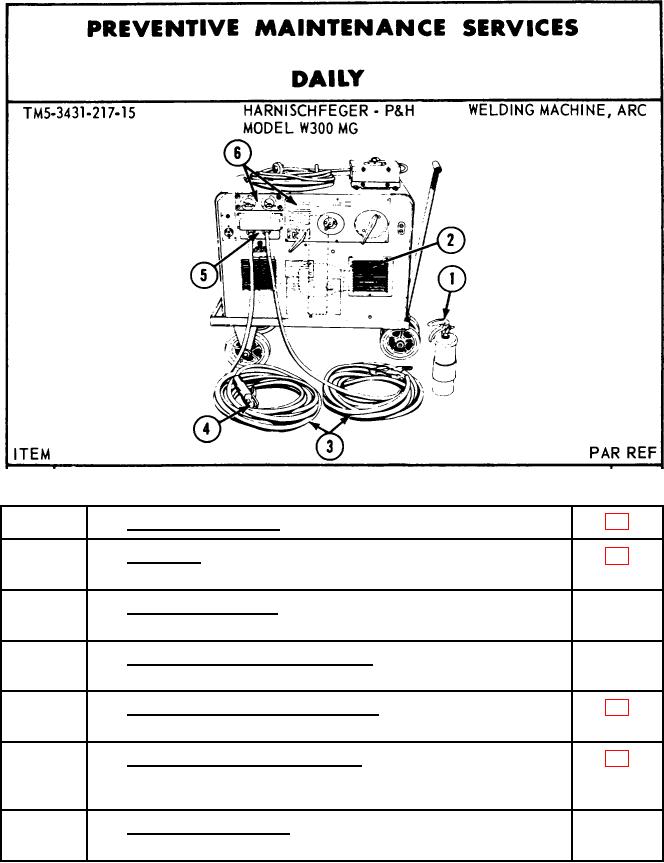

1

FIRE EXTINGUISHER. Inspect for broken seal (Weekly).

2

BRUSHES. Inspect to see that brushes move freely in brush

holder and make firm contact.

3

CABLE ASSEMBLIES. Inspect cable assemblies. If damage is

apparent repair or replace immediately.

4

ELECTRODE HOLDER ASSEMBLY. Inspect electrode for

general condition. Replace if defective.

5

TERMINAL BOARD CONNECTIONS. Tighten loose cables or

mountings.

6

CONTROLS AND INSTRUMENTS. Inspect for damage and

loose mountings. With unit operating check for proper operation.

Replace defective instruments.

NOTE 1: OPERATION. During operation observe for any

unusual noise or vibration.

MEC 3431-217-15/8

Figure 8. Daily preventive maintenance services..

AGO 8244A

17