TM 5-3431-203-15

Section X. GAS AND WATER SOLENOID VALVES

3-48. General

The gas solenoid valve is used when the op-

erator is performing inert-gas welding. The

solenoid valve is operated electrically through

the timer control. The waker solenoid valve is

used when a water-cooled torch is used. The

water solenoid valve is operated electrically

through the timer control.

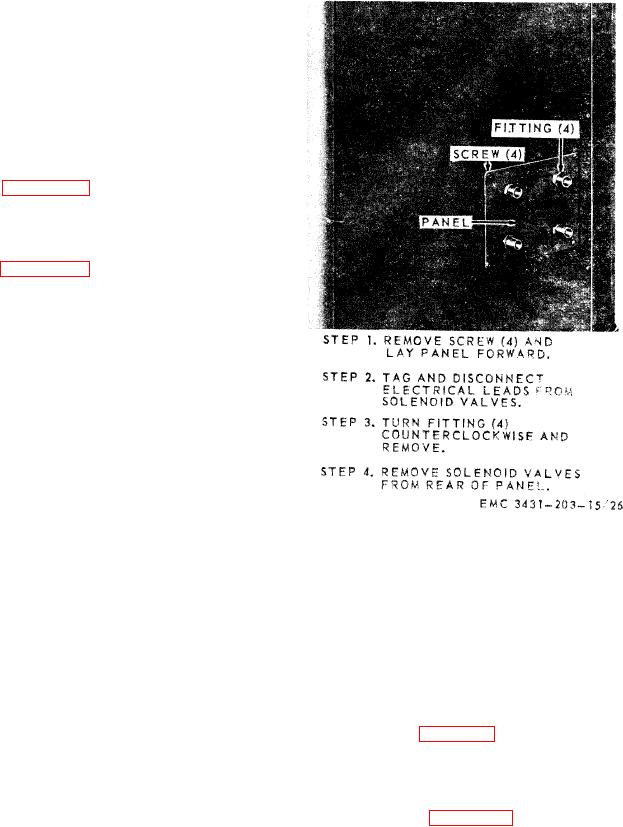

3-49. Gas Solenoid Valve

Refer to figure 3-17 and remove and in-

stall the gas solenoid valve.

3-50. Water Solenoid Valve

Refer to figure 3-17 and remove and install

the water solenoid valve.

and installation.

Section XI. VENTILATING-COOLING SYSTEM

3-52. Fan, Motor, and Guard Assembly

3-51. General

a. Removal.

The welding machine is cooled by a fan mo-

tor assembly which operates from the acces-

(1) Remove the welding machine top and

sory power transformer. It has four aluminum

housing (para 3-26).

blades which pull the air through the welder

(2) Disconnect the motor leads from the

and out the back, The ballast resistors are

top and bottom terminals of the ac-

mounted on the fan guard so that they can

cessory transformer.

be cooled by the air as it passes through

(3) Refer to figure 3-1 and remove the

them. TO make any repairs on the motor fan

fan, mater, and guard as a complete

blade, or guard, the complete assembly must

unit.

be removed.