TM 5-6115-586-34

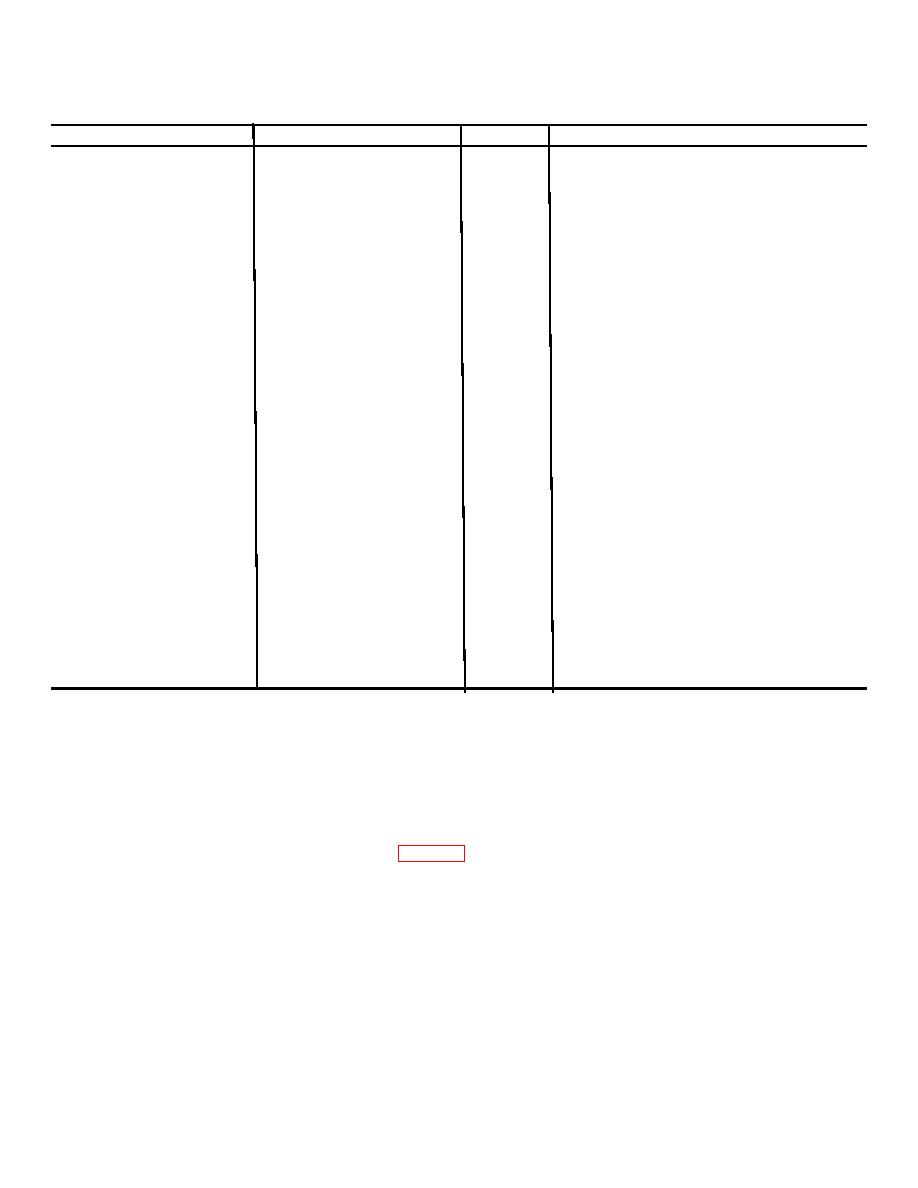

Table 2-5. Power Plant Operating Limits (Gas Turbine Engine)

Type

Limit

Tolerance

Remarks

(1) Leakage

One drop per minute

Maximum

From accessory drain only. Fuel leakage from

(a) Fuel

plenum drain is permitted only after a false

start or blowout.

(b) Oil

One drop per 15 minute period Maximum

From accessory drain.

(2) Acceleration time

60 seconds

Maximum

Starting after 5 psig oil pressure is attained.

(3) Temperatures:

(a) Turbine

1300F (705 )

C

Absolute

Caution: This temperature must not be

maximum

exceeded at any time under any operating

circumstances.

(b) Turbine

1225F (663C)

Maximum

Maximum allowable temperature for continous

operation.

(4) Oil consumption

0.25 lb/hr

Maximum

Under all operating conditions.

(5) Starter motor duty cycle

One minute on one minute off Maximum

Cool the starter before repeating duty cycle. Do

or 5 starts in 10 minutes.

not exceed 28,000 rpm turbine speed with

the starter energized.

(6) Turbine Wheel Speeds

100 rpm

(a) Continuous operation

40,700 rpm

Full-load condition.

(b) Continuous operation

41,600 rpm

Maximum

No-load condition.

(c) Absolute maximum

44,500 rpm

(d) 10-second operation

42,500 rpm

Maximum

Do not operate at a speed in excess of 42,500

rpm for longer than 10 seconds.

(7) Vibration:

(a) Accessory pickup

0.6 mil at any frequency

Maximum

Maximum peak vibrations greater than the

limits shown may occur at certain critical

turbine wheel speeds from 17.000 to 23,000

rpm.

Caution: Do not operate the unit con-

tinuously at any speed where vibration

exceeds these limits.

(b) Turbine end pickup.

0.4 mils

At any frequency.

d. Preliminary Test Procedure.

(1) Check that instrumentation calibration is current.

(2) Remove all accessory components from stowage compartments. Visually check at this time for loose or

damaged lines, fittings, and wire harnesses.

(3) Secure all access doors that are not normally to be open or removed during testing.

(4) Connect instrumentation called out in table 2-3.

(5) Check that oil tank is filled with oil.

(6) The unit shall be stopped and started in accordance with operating instructions on the control panel.

(7) Record turbine engine and two air conditioner hourmeter readings when power plant is installed in test

setup.

(8) Prime fuel and oil as follows:

(a) Remove electrical connector 'from the oil pressure fuel sequencing switch.

(b) Disconnect fuel boost pump connector and connect to a 24 vdc lamp. Acutate master switch to RUN,

lamp shall not glow. Actuate master switch momentarily to START, lamp shall glow. If the preceding tests check

correctly, reconnect fuel boost pump connector.

2-13