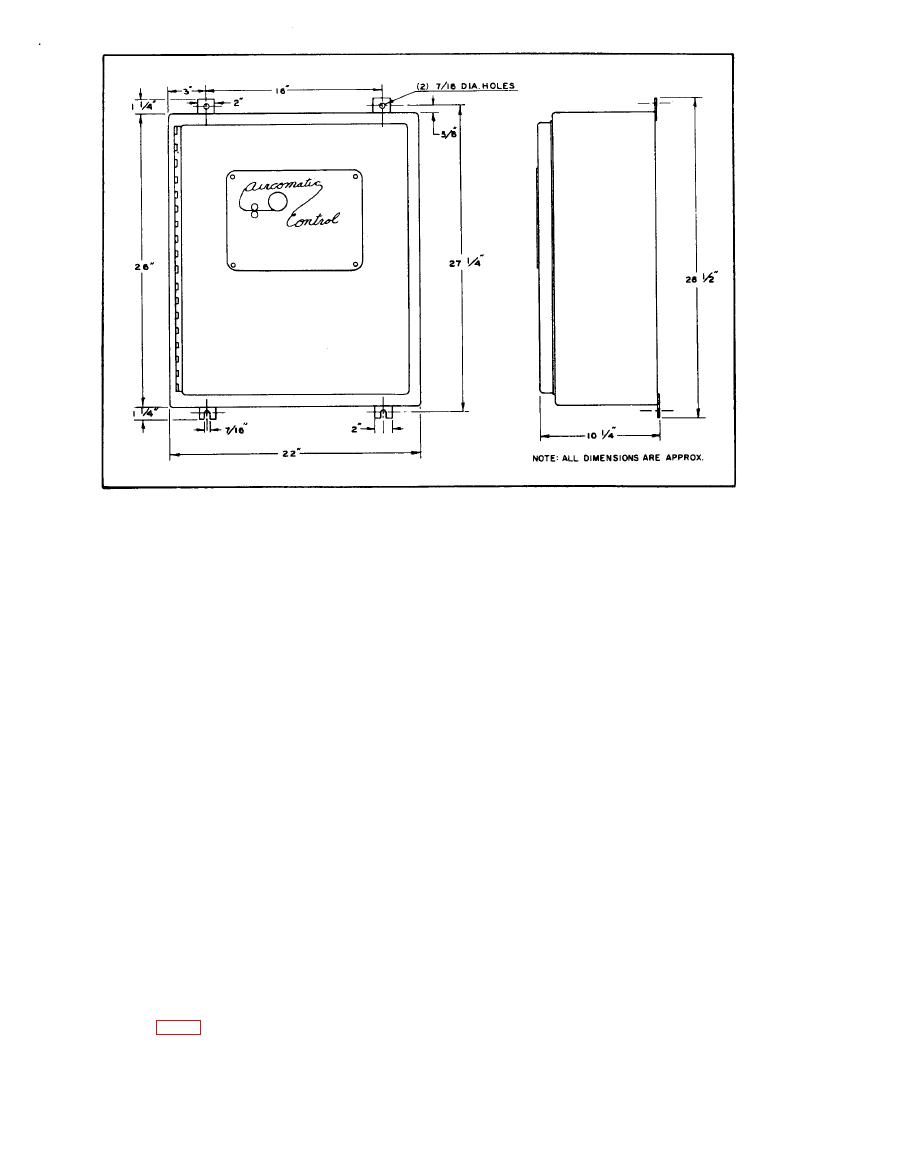

Fig. 2 Dimensions

contains a printed circuit board with a rectifier, am-

1.3 SUPPORTING EQUIPMENT

plifiers, voltage regulators, resistors, capacitors,

Supporting equipment includes other basic components

and a saturable reactor. These comprise a full-wave

which must be used in a system with the Control such

rectifier, a motor control circuit, and a motor-run

as an AIRCOMATIC push or pull welding gun and a

circuit.

Model AHF-E Push-Pull Wire Feeder.

1.2.2 OPERATING CONTROLS AND INDICATORS

The controls and indicators used for operation of the

Control are a main power switch, a power-ON indi-

cator lamp, a wire feed selector switch, a wire feed

calibration rheostat, and a rough-service lamp re -

sister.

Section Il. INSTALLATION

This section covers installation of the Control and

2.2 LOCATION AND MOUNTING

interconnection with all basic components needed for

the operation of an AIRCOMATIC welding system.

Choose a location for the Control that will have free

and easy access. Allow for complete opening of the

2.1 UNPACKING, INSPECTION AND ASSEMBLY

tinged door. Make certain there will be sufficient

Unpack the Control carefully so as not to damage any

space for connecting cables and hoses at the base,

parts or mar any finished surfaces. Check the en-

closure, both inside and out, for any signs of damage,

Unwrap the tubes and capacitors, and install these on

Secure the Control to a wood panel. Place it so that

the Control chassis (Fig. 3). Report any damage im-

the Power-ON lamp atop the Control will be at aver-

mediately to your nearest AIRCO representative.

age eye-line height.