Section Ill. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

parts are listed and illustrated in Appendix D of

this manual,

No special tools or equipment are required b y

direct and general support maintenance for the

maintenance of this welding machine.

No specially designed book and equipment are

required for direct and general support mainte-

nance of this welding machine.

tenance Repair Parts

Direct and General support maintenance repair

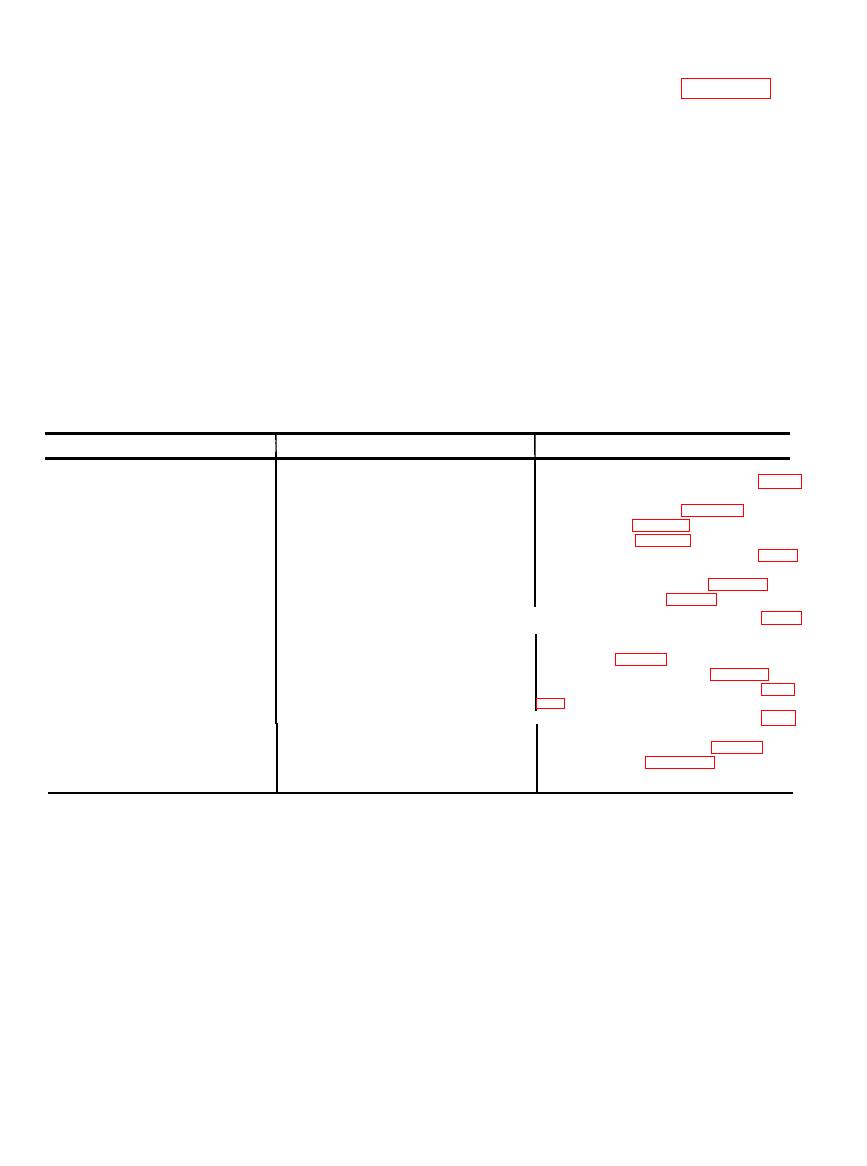

Section IV. TROUBLESHOOTING

its components. Each malfunction stated is fol-

58. General

lowed by a list of probable causes of trouble. The

This section provides information useful in

corrective action recommended is described oppo-

diagnosing and correcting unsatisfactory opera-

site the probable cause.

tion or failure of the welding machine or any of

Table 5-1.

Troubleshooting

Malfunction

Probable cause

Corrective action

a. Repair or replace transformer (para

1. Welding Machine Smokes

a. Main transformer defective -------- --

6-28).

Excessively.

b. Replace transformer (para 6-27).

b. Control transformer defective ------ ---

Polarity selector switch defective-

---

Replace switch (para 6-3).

2. Polarity Cannot be Selected . . . ..

Replace switch (para 6-3).

Range selector switch defective- ---------

3. Range Cannot be Selected . . . . . . .

a. Repair or replace transformer (para

a. Main transformer defective - -------

4. Welding Maching Fails to Start- -

6-28).

b. Repair or replace wiring (para 6-30).

b. Wiring defective ---------------------

a. Replace rectifier (para 69).

5. Welding Machine Operates

a. Power rectifier defective- ------------

b. Replace output control rheostat (para

Erratically.

b. Output control rheostat defective- ----

6-4).

c. Clean or straighten contacts, or replace

c. Range switch contacts dirty, greasy or

range switch (para 63).

bent.

a. Repair or replace wiring (para 630).

a. Wiring shorted -------------- --------

6. Contactor Breaks Circuit---- ----

b. Repair or replace transformer (para

b. Main transformer shorted----------

a. Replace output control rheostat (para

7. No Current Control -------------

a. Output control rheostat defective ----

6-4) .

b. Control rectifier defective --------

b. Replace control rectifier (para 6-9).

c. Replace dc coil (para 614).

c. Saturable reactor dc coil shorted,

grounded or open.