Section IV. OPERATING UNDER USUAL CONDITIONS

2-9. General

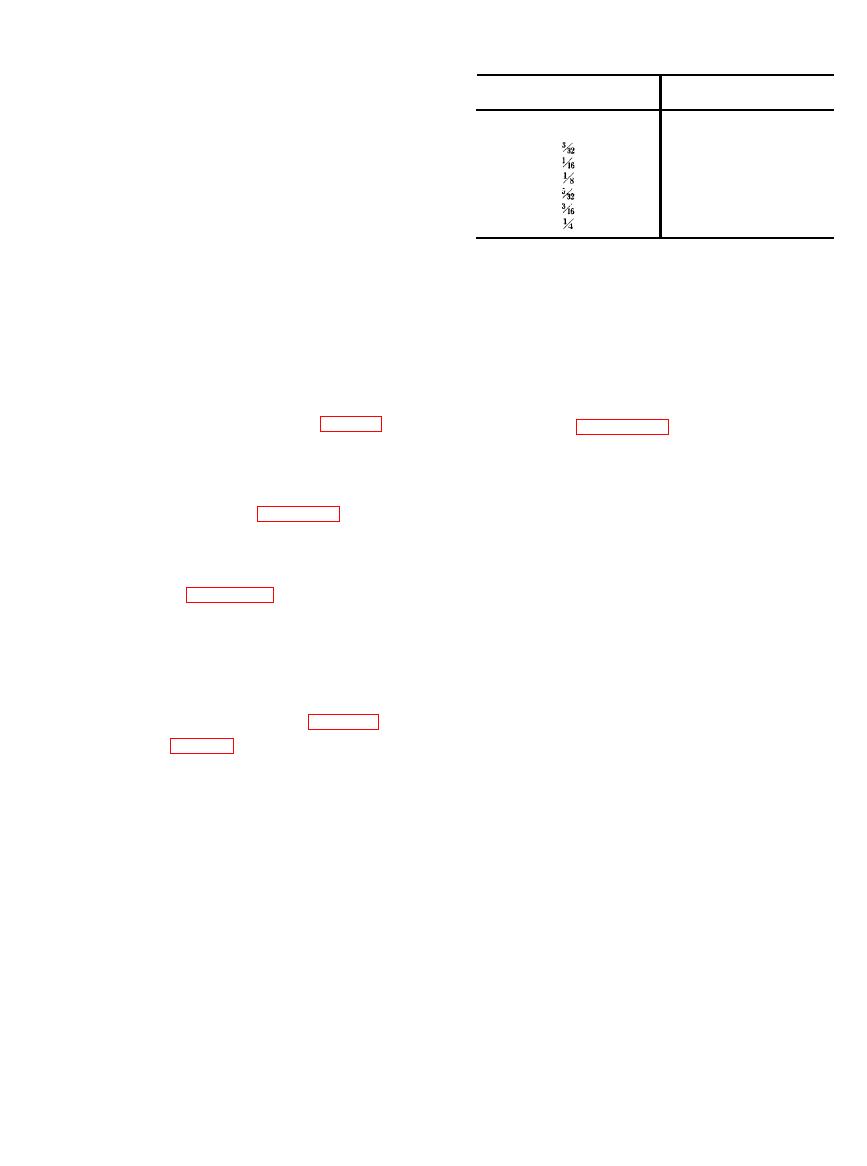

Tungsten electrode size

Welding current

a. The instructions in this section are published

(diameter)

(amp)

for the information and guidance of the personnel

responsible for operation of the welding machine.

0.040 in.

4060

in.

50100

b. The operator must know how to perform

in.

100-160

every operation of which the welding machine is

in.

150-210

c a p a b l e . This section gives instructions on

in.

200-275

in.

250-350

starting and stopping the welding machine, basic

in.

325-475

capabilities of the welding machine, and various

settings of controls to enable the welding machine

to perform different types of welding for which it

c. Test for proper setting, Use a sample piece of

is designed. Since nearly every job presents a dif-

metal, like the metal to be welded and adjust the

ferent problem, the operator may have to vary

welding amperage to produce the correct arc nec-

given procedures to fit the individual job.

essary for the welding to be done.

Warning: Do not come in contact with the

2-10. Starting

electrode while the welding machine is operating.

a. Preparation for Starting.

The high voltage generated by the machine can

cause death by electrocution.

(1) Perform the necessary daily preventive

maintenance checks and services ( para 35 ).

the welding machine.

(2) Clean area on item to be welded to make a

good connection.

Warning: Before operating the welding ma-

chine see that the ground terminal lug is con-

(3) Connect the ground clamp.

nected through the input cable or by separate con-

ductor to the power system ground. An un-

start the welding machine.

grounded welding machine can cause death by

electrocution to personnel coming in contact with

2-11. Stopping

it.

Note. This welding machine is equipped with a remote

welding machine,

receptacle and can be operated by remote control. When

using remote control, the panel control-remote centrol

b. Remove ground clamp from item which was

switch must be in the remote control position. When re-

being welded.

mote control is used, the maximum current available will

be limited by the setting of the output panel rheostat, If

full range is necessary, the panel output control rheostat

2-12. Operation of Equipment

must be set wide open. The welding machine is also

equipped with a remote contactor control receptacle for

activation of the contactor by a foot switch and a remote

contactor receptacle for activation of the contactor by an

trode.

external 115 volt ac source.