TM 5-3431-201-10

Section III. OPERATION OF EQUIPMENT

12. General

a. The instructions in this section are published for

the information and guidance of the personnel

responsible for operation of the welding machine.

b. The operator must know how to perform every

operation of which the welding machine is capable. This

section gives instructions on starting and stopping the

welding machine. Since nearly every job presents a

different problem, the operator may have to vary given

procedures to fit the individual job.

13. Starting

a. Preparation for Starting.

(1) Perform the before-operation services

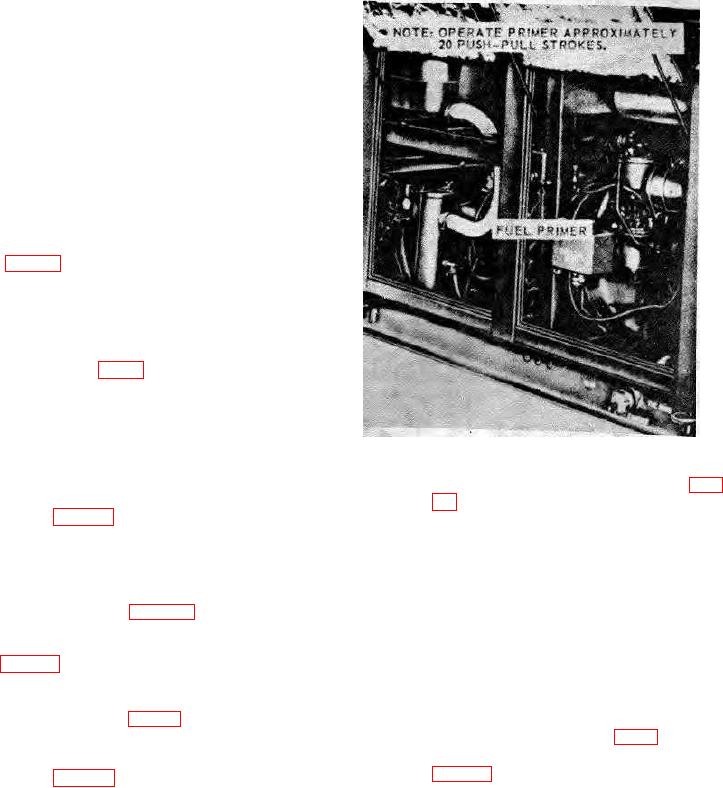

(2) The fuel system must be primed: When

starting the engine for the first time, after

shipment, or if it has run out of fuel or has

stood idle for an extended period of time.

To prime the fuel system, operate the

hand primer (fig. 5). Remove the bleeder

plug from the top of the fuel filter and fuel

strainer. Operate the hand primer until all

air is bled from the lines. Install the

bleeder plugs.

Figure 5. Fuel system, primer instructions.

b. Starting the Engine.

(1) Perform the preparation for starting

(2) Perform the after-operation services (par.

procedures as instructed in a above.

(2) Refer to figure 6 and start the engine.

b. Stopping by Safety Devices. The engine is

c. Cold Weather Starting.

equipped with safety devices which will stop the engine

in the event of a loss of oil pressure, high coolant

(1) Perform the preparation for starting

temperature, low fuel pressure, or engine overspeed.

procedures as instructed in a above.

(2) To start the engine in temperatures 32o F.

These devices, when actuated, will cause the engine to

stop. If the engine stops due to an overspeed condition,

or below, refer to figure 7 and inject an

the governor will reset itself. In the event the engine

ether capsule into the primer, neck first.

stops due to defects other than lack of fuel, oil, or

Operate the ether primer as described in

coolant, report the condition to organizational

maintenance.

(3) In extremely cold temperatures, it will be

15. Welder Operation

necessary to use the winterization heater

a. Welding Machine.

for winter starting (par. 24).

(1) Attach the welding cables (fig. 9).

14. Stopping

a. Normal Stopping.

(2) Operate the welding machine as shown by

(1) Refer to figure 8 and stop the engine.

15