trol to maintain proper engine operating tem-

e. Connect hose from manifold heater to air

perature.

filter intake.

h. Begin usual welding operations.

f. Start coolant heater in accordance with

a. When the installation is permanent, erect

a protective cover for it. When a temporary

installation is made, take advantage of natural

i. Close side doors and adjust shutter control

barriers whenever possible. All side doors, other

than control panel door, should be closed when-

to maintain proper engine operating tempera-

ever possible during operation. Keep the unit

ture.

as clean as possible, paying special attention

to the engine radiator.

216. Stopping Engine in Extreme Cold

b. In dusty or sandy areas the lubricating

filter and air cleaner must be cleaned more

(Model LEW 300 only).

f r e q u e n t l y than under normal conditions.

2-13.

Clean all lubricating points before and after

lubrication. Be sure that all lubricant contain-

ers are tightly sealed and stored in an area

as free as possible from dust and sand.

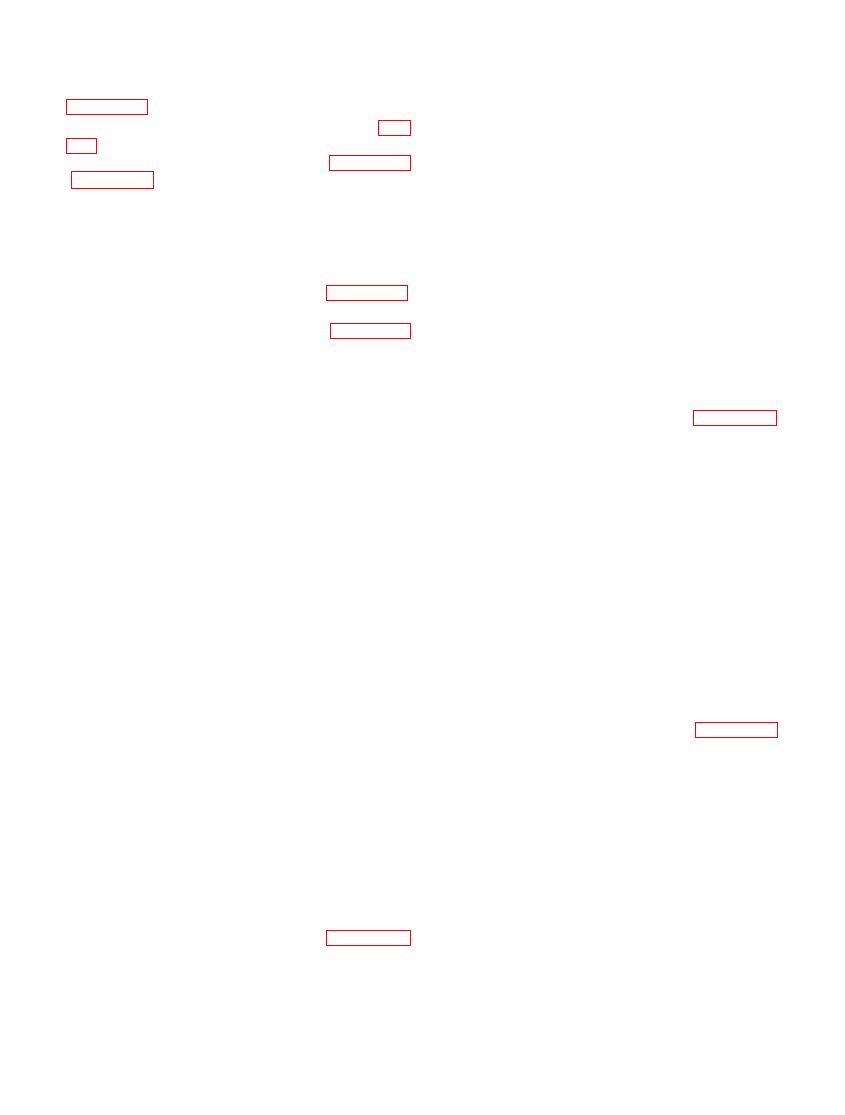

Freezing Points

Freezing

Speceific gravity

points (O F.)

Battery condition at 80 F.

graph 2-12.

1.280 - - - - Fully charged - - - - - - - - - - - - - - - -90

d. Close side doors and adjust shutter con-

1.250 - - - - - 75% charged - - - - - - - - - - - - - - - - - - 62

trol to maintain proper engine operating tem-

1.200 - - - - - 50% charged - - - - - - - - - - - - - - - -16

1.190 - - - - - 25% charged - - - - - - - - - - - - - - - - -10

perature.

1.150 - - - - - Almost totally discharged - - - +5

e. Begin usual welding operations.

1.100 - - - - - Totally discharged - - - - - - - - - - - +19

a. Keep cooling system free of rust and

Conditions

a. When the welding machine is operated

scale. If necessary add an approved rust in-

outside, erect a shelter to protect the unit

hibitor. Clean and flush the cooling system at

when possible. If the erection of a shelter is

frequent intervals. Do not use salt water in

not practical, keep the machine covered with

cooling system except in extreme emergencies.

a canvas. Remove the covering during dry

Make sure the engine thermostat is working

periods, open all doors and allow the unit to

properly. Inspect the V-belts for proper ad-

dry. Keep the fuel tank as full as possible to

justments.

prevent the forming of condensation.

b. Lubricate the engine in accordance with

the current lubrication order.

c. Do not fill the fuel tank to the top; allow

graph 2-12.

sufficient room for expansion of the fuel.

c. Close side doors and adjust shutter, con-

d. Inspect the electrolyte level of the bat-

trol to maintain proper engine operating tem-

teries daily. The electrolyte level should be

perature.

three-eights inch above the plates. Add water

d. Begin usual welding operations.

as necessary.

e. Make sure the welding machine is free

of airflow restrictions. When operating in-

u. Salt water causes corrosive action on

doors, make provisions for adequate ventila-

metal. Care must be taken to avoid contact of

tion and the venting of exhaust fumes to the

equipment with salt water. If contact is made,

outside.

or if the unit is exposed to salt spray, wash

the unit with clean, fresh water.

graph 212.

Caution: The cooling system is not de-

g. Close side doors and adjust shutter con-

AGO 20030A