selector to desired setting, so that necessary

metal application, no change of current is de-

arc can be produced.

sired. During welding for this purpose, job

selector should be set in black section for a

medium-high open-circuit voltage (normal

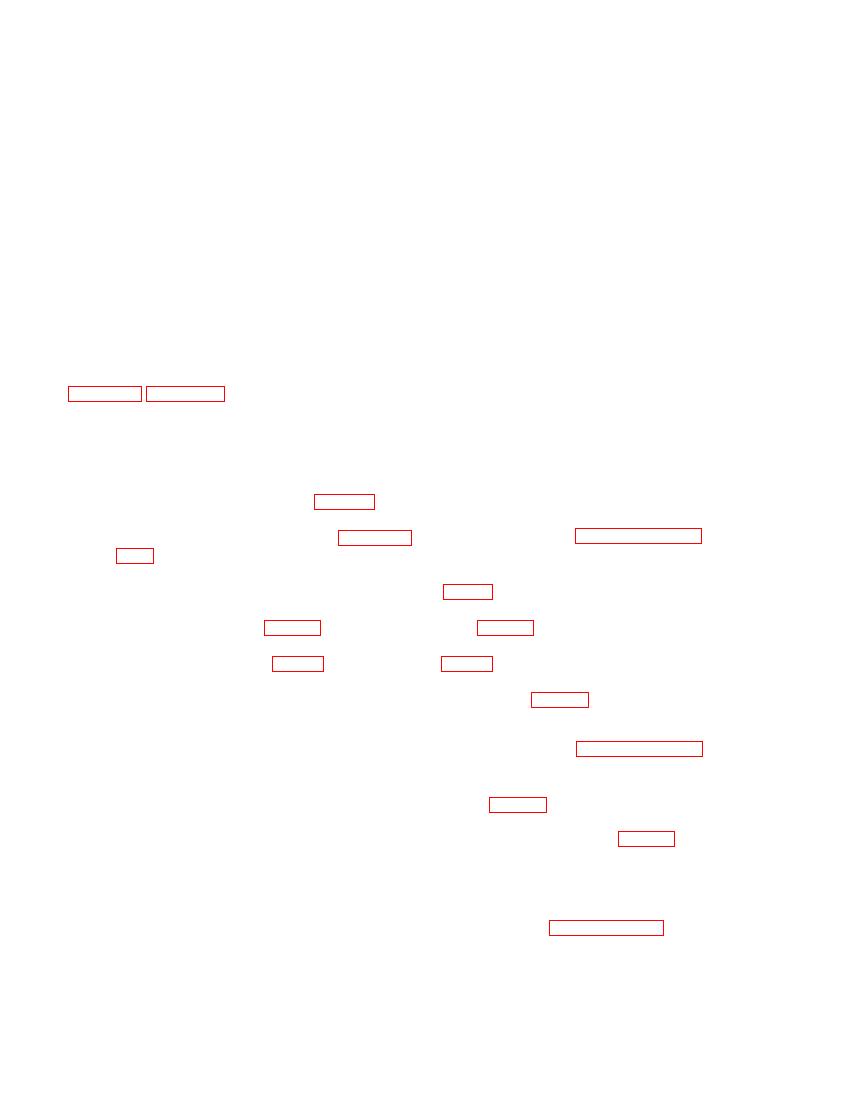

Coated Electrodes

welding range). Little current change will re-

Lengths

Electrode diameter

Current

mlexcitmoum

Ea r de

sult from lengthening or shortening arc when

(in.)

(in.)

minimum

(amps) (amps)

job selector is in this position.

70

11 1/2

3/32

90

(3) When a "rubbery" arc or large elec-

110

14 or 18

135

1/8

trodes and high currents is desired for welding

14 or 18

180

150

5/32

operation, job selector should be set in the

180

14 or 18

220

3/16

yellow section for a high open-circuit voltage

1/4

250

300

14 or 18

300

425

14 or 18

(large electrodes range) .

5/16

450

14 or 18

3/8

550

(4) For special jobs requiring the small-

est sizes of electrodes and very low current

values, job selector should be set in the special

and Slag Types of Electrodes

applications section for a low open-circuit

Gaseous types

voltage.

Slag type

Flat position Vertical and

Electrode

(amps)

overhead

diameter

(5) The approximate current range for

position

(in.)

positions

(amps)

(amps.)

bare and lightly coated electrodes is shown in

60

60

3/32

130

110

for gaseous and slag types of electrodes.

120

1/8

160

150

140

5/32

c. Dual Control. Dual control of amperage

200

160

175

3/16

and voltage can be accomplished by use of job

300

200

1/4

selector and continuous current control. The

400

325

5/16

dual control is utilized by the following steps:

500

425

3/8

(1) Place polarity switch (fig. 2-2) in

d. Operation as an Arc Welder.

the OFF position.

(1) Refer to paragraph 2-12 and start

(2) Start engine in accordance with para-

engine.

graph 2-12 and allow it to warm up.

(2) Connect welding cables to terminals

(3) Place the polarity switch in ELEC-

TRODE POSITIVE or ELECTRODE NEGA-

TIVE as required.

(3) Place polarity switch in desired posi-

tion (fig. 23).

(4) Set job selector (fig. 2-2) to desired

voltage.

(4) Place job selector in proper position

(5) Set current control (fig. 2-2) to de-

sired amperes.

(5) Set current control in corresponding

(6) Strike an arc.

color range (fig. 2-3 ).

(7) If arc is weak, turn job selector up.

If arc is too cold, turn current control up 10

(1) Refer to paragraph 2-12 and start

or 20 amperes and turn job selector down.

engine.

Warning: Do not adjust welding con-

(2) Place idle control switch in OFF po-

trols while maintaining arc.

sition (fig. 23).

(8) If, when correct current is obtained,

( 3 ) Place auxiliary generator circuit

job selector is positioned beyond desired set-

breaker in ON position (fig. 2-3).

ting, adjust current control up and return job

Section V. OPERATION UNDER UNUSAL CONDITIONS

antifreeze. Before adding initial antifreeze,

clean and flush the entire cooling system in

OF.)

a. Lubricate the engine in accordance with

accordance with paragraph 3-39. Inspect cool-

the current lubrication order.

ing system for signs of leaks or other damage.

b. Inspect the engine cooling system to as-

Inspect shutter control for proper operation.

sure that it contains the proper mixture of

Caution: Do not bend or kink coolant

AGO 20030A