PREVENTIVE MAINTENANCE SERVICES

QUARTERLY

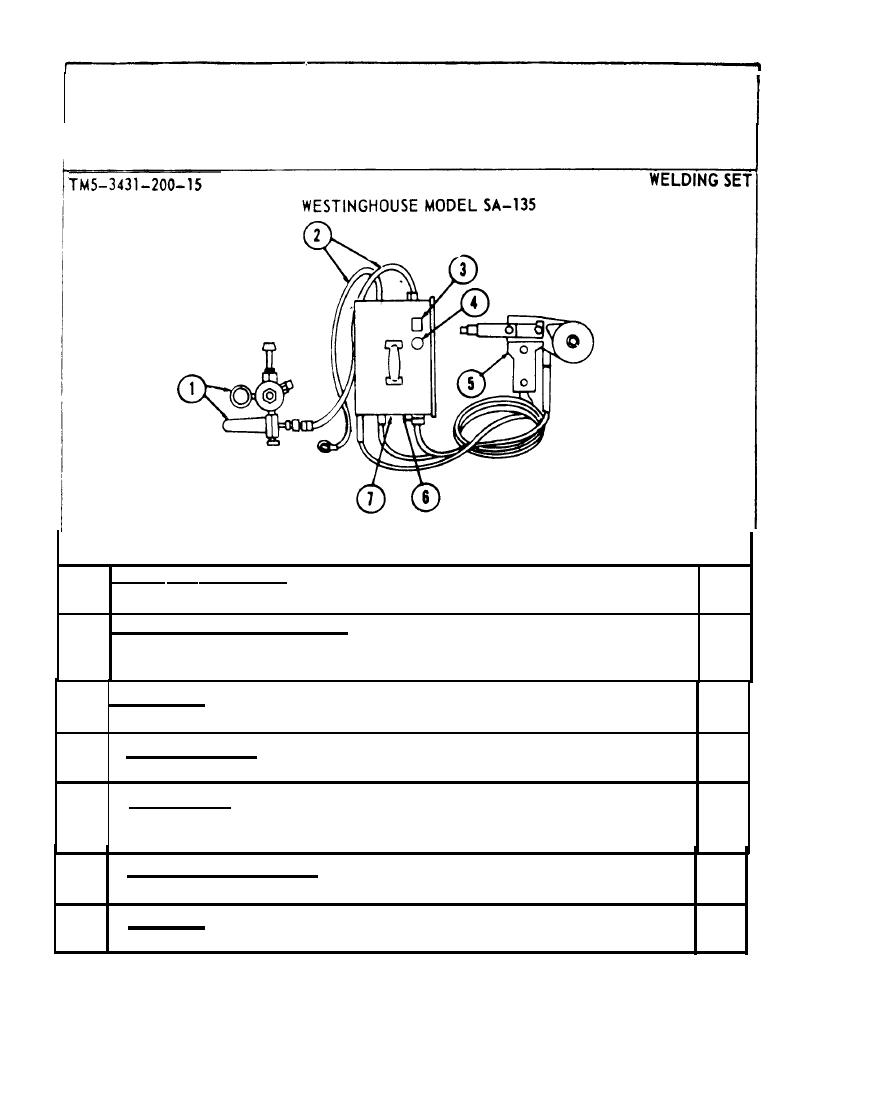

LUBRICATE IN ACCORDANCE WITH CURRENT LUBRICATION ORDER

ITEM

PAR REF

1

A R G O N G A S REGULATOR,.

Inspect

for

cracks,

leaks, and Improper

operation.

HOSE AND CABLE ASSEMBLIES,

Inspect for worn, frayed, and other

2

damaged conditions.

!nspect for loose connections on the hose

and electrical cables.

Inspect

for

defective

wiring.

Test

the

contactor

for

CONTACTOR.

3

improper operation.

Inspect for leaks and

loose

electrical

connec-

SOLENOID VALVE.

4

tions. Test for improper operation.

.

WELDING GUN.

Inspect

for

cracks, Ieaks, loose nose, and elec-

5

n o z z l e , adapter, guide tube, gun tube,

trical connections; the

and gun barrel for weld

spatter, and obstructions.

J

F U S E AND FUSE HOLDERS

Inspect for damaged holders, loose elec-

6

trical connections, and for defective or missing fuses.

CONTROLS.

Inspect the controls

for damage.

With

the

unit

52

7

operating,

inspect for improper

operation.

Figure

8.1.

(Added)

Quarterly

preventive

maintenance

services.

4