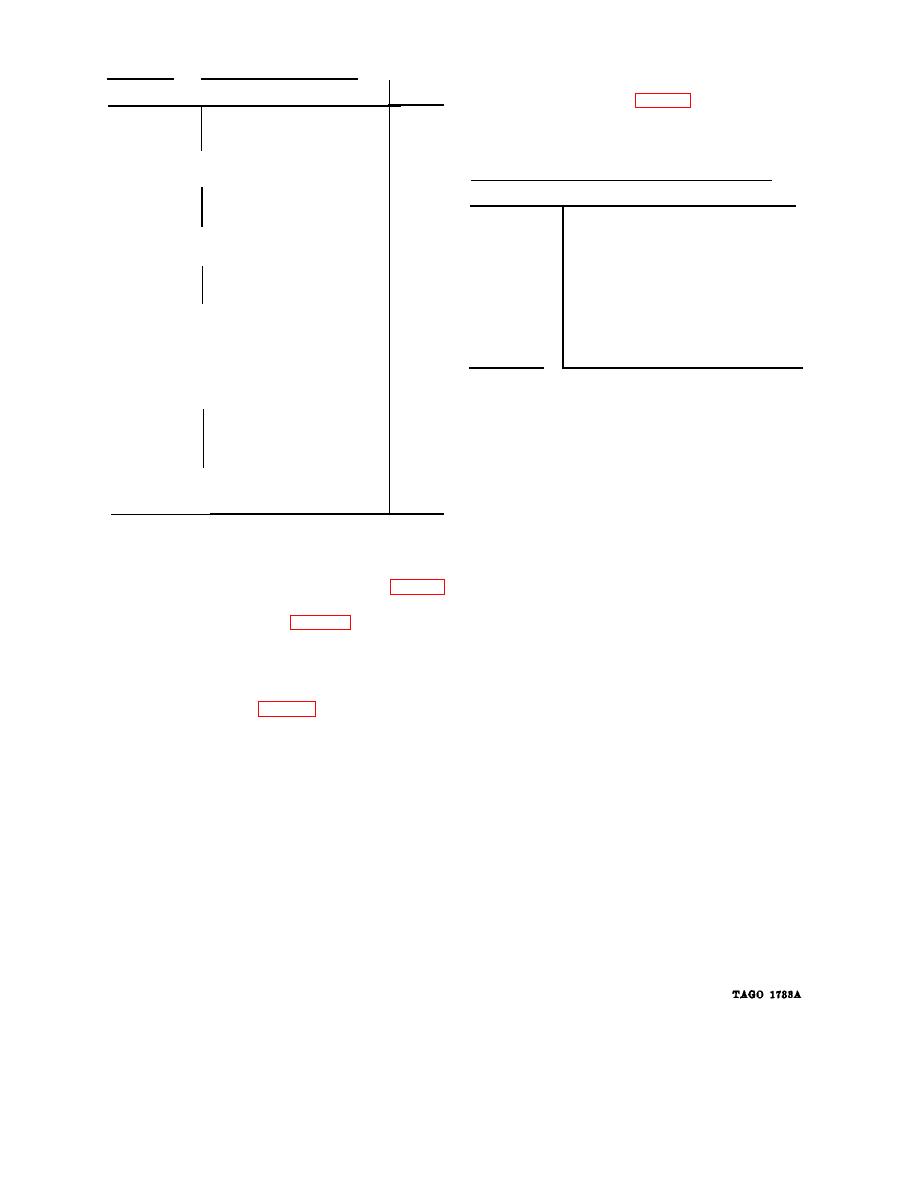

Table 1. List of Materials

j. Recommended electrodes to be used with the

converted holders for cutting and repair work on

Description

Quantity

Federal stock No.

weldments are listed in table 2 for information

only. Requisitioning of required stocks must be

1or2

CLAMP, HOSE: 1 to 2 dia,

4730-844-2221

accomplished through supply channels.

0.562 w, 0.025 thk, passi-

vated finish (1 reqired for

common type holders, 2 re-

quired for collet type

Federal stock No.

Description

holders).

1

COCK, DRAIN: br, thd end

4820-142-3036

ELECTRODE,

AND

3439-262-4227

CUTTING

connection, w/o thds on

WELDING: graphite type, 3/16 dia,

free flow end, NPT thd,

12 lg.

105 psi pressure rating.

ELECTRODE,

CUTTING

AND

3439-262-4294

1

COUPLING, PIPE: CI,

4730-639-9167

WELDING: graphite type, 1/4 dia,

NPT thd, 1.060 lg, 150 psi

12 lg.

steam pressure, Fed Spec

AND

ELECTRODE,

CUTTING

3439262-4228

WW-P-521, type 1.

WELDING: graphite type, 3/8 dia,

1 ro

INSULATING TAPE,

5970-538-5843

12 lg.

ELECTRICAL: adhesive

cotton, 0.075 in. w, 180 ft

lg, 0.015 in. thk, dielectric

strength per Spec MIL-I

15126, type CFT.

ports of errors, comments, and/or suggestions are

1

TUBE, COPPER: plain

4710-606-7915

encouraged. They should be submitted on DA

ends, seamless, annealed,

Form 2028 (Recommended Changes to DA Pub-

12.250 in. lg, 1,000 psi

lications) and forwarded direct to Commanding

hydrostatic teat pressure,

General, Headquarters, U.S. Army Weapons

Fed Spec WW-T-799,

C o m m a n d , ATTN: AMSWE-SMM-P, Rock

type N.

Island Arsenal, Rock Island, Ill. 61201.

Section II. CONVERSION OF COMMON TYPE ELECTRODE HOLDERS

coiled spring (slightly larger in diameter than the

tube) slipped over the tube at the desired spot

converted by assembling items listed in table 1

will prevent kinking the tube while bending and

and attaching them to the holder as described

is then easily removed by sliding it along the tube.

below and as illustrated in figure 1.

c. Insert the tube through the drilled hole and

cut it off so it protrudes approximately 1/8 inch past

hose parts and assemble them to the holder as

the opposite edge of the holder jaw.

follows:

d. Remove the tube from the jaw and attach the

a. Drill a hole in the base jaw of the holder as

cock to the air hose using the pipe coupling and/or

shown in the insert on figure 2. It is suggested that

other fitting(s) as required.

the drilled hole be only slightly larger than the

e. Insert the tube in the drilled hole in the holder

outside diameter of the copper tube. A snug fit is

jaw, place the attachment on the side of the holder

required to insure rigidity of the tube so it cannot

as shown, and secure with the radiator hose clamp.

be misaligned since the air stream must be directed

When securing the cock to the handle, place the

on the approximate spot of contact of the electrode

clamp as far forward as possible so there is a

with the workpiece.

minimum of interference with the handling of the

b. Braze the copper tube to the unthreaded end

holder.

of the drain cock. Place the cock on the holder

f. Using the electrical tape, tape the hose to the

handle near the front as shown, estimate the

rear of the handle and around the cock, cover the

distance between the cock and the drilled hole,

clamp and other metal parts of the attachment

and bend the tube at 90. Care must be taken not

with tape to insulate these parts and preclude

to bend the tube too sharply as this may restrict

danger of electrical shock to the operator.

air flow through the tube. An ordinary tightly-

2