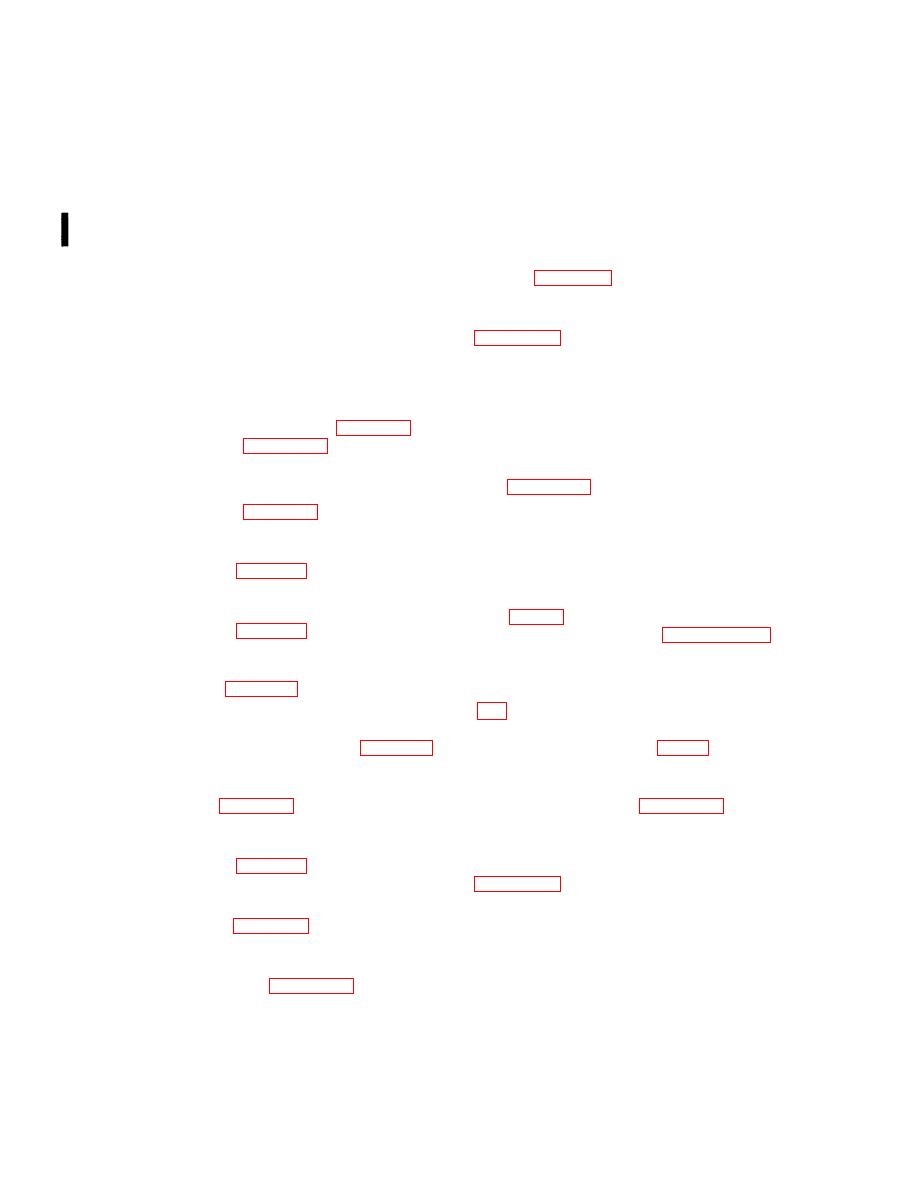

TM 55-4920-404-30&P

APPLICABLE SUPPLY

MANAGED

CATALOG

NSN

LIN

SHOP SET

SHELTER BY

Hydraulic

T26065

TSARCOM

SC-4920-99-CL-A91

S-280

HYAM

Welding

TSARCOM

T26085

SC-4920-99-CL-A91

S-280

WEAM

T25961

Armament

ARRCOM

TM 9-4933-223-14&P

4933-00-122-6771

SPAM

T25981

ARRCOM

Fire

TM 9-4931-371-14&P

4931-00-122-7088

SPAM

Control

CERCOM

Not available

Z68167

Battery

S-280

NSN Pending

refer to figures D-1 thru D-20.

1-9. SHELTER FEATURES.

a. Base frame and brace installation for the

a. Standard Shelter Features.

work table is illustrated in drawing 4920-EG-070,

(1) SPAM shelters. Refer to TM 10-5410-224-

14 for details of shelter features.

CAUTION

(2) S-280 shelters. Detail features for basic S-

280 shelters are found in TB 750-240.

The base frame and brace installation

form an integral part of the work

(3) Modifications to the basic S-280 shelter

table and should not be removed.

are found in drawing 4920-EG-056, figure D-1 and,

drawing 4920-EG-080, figure D-20.

b. The assembly and installation of the General

Purpose Table is illustrated in drawing 4920-EG-

b. Specific Features.

072, figure D-15, and is secured to the shelter floor

(1) Tool crib - SPAM mounted. Refer to

for shipping only.

drawing 4920-EG-060, figure D-3 for specific de-

c. The environmental control unit (ECU) for the

tails.

SPAM is secured to its support through the opening

(2) Sheet metal - SPAM mounted. Refer to

in the foldout end wall of the expandable shelter for

drawing 4920-EG-061, figure D-4, for specific fea-

operation and secured to the floor of the SPAM

tures of installation.

using bracket assembly (item 2, drawing 4920-EG-

(3) Hydraulic - S-280 mounted. Refer to

071, fig. D-14 for storage and shipment. For instal-

drawing 4920-EG-062, figure D-5, for specific fea-

tures for installation.

5410-224-14 for details.

(4) Rotor - SPAM mounted. Refer to draw-

d. The environmental control unit (ECU) for the

ing 4920-ECX-063, figure D-6, for specific feature of

S-280 shelter is secured to its support (item 11, fig,

installation.

shelter for operation and secured to the floor using

(5) Electrical and instrument - SPAM

mounted. Refer to drawing 4920-EG-064, figure D-

bracket assembly (item 6, fig. D-1) for storage and

7, for specific features of installation.

shipment.

e. Fire extinguisher and bracket as illustrated in

(6) Welding - S-280 mounted. Refer to draw-

ing 4920-EG-065, figure D-8, for specific features of

drawing 4920-EG-075, figure D-17, for the SPAM

installation.

shelter are secured to the wall left of the cargo door.

f. The Creeper 4910-106-7834 is used to make

(7) Machine - SPAM mounted. Refer to

the tool tray assembly per drawing 4920-EG-069,

drawing 4920-EG-066, figure D-9, for specific fea-

tures of installation. -

g. Unpacking and cleaning of tool components of

(8) Powertrain - SPAM mounted. Refer to

drawing 4920-EG-067, figure D-10, for specific fea-

shop set will be performed as follows:

tures of installation.

(1) Components of the tool set will normally

be boxed and strapped to the shelter floor. Remove

(9) Turbine engine - SPAM mounted. Refer

web straps securing boxed components of the shop

to drawing 4920-EG-068, figure D-11, for specific

set.

features of installation.

(2) Unpack components of shop set from box-

1-10. SHELTER COMPONENTS AND LO-

es. Remove preservative material from tools and

CATIONS. For shelter components and location,

Change 1