The location and function of the controls used in the

3.2 GENERAL

operation of the Feeder are listed in Table IV. Also

l i s t e d are components closely related to Feeder

The Feeder should only be operated when connected

operation.

within an AIRCOMATIC welding system, This sec-

tion covers only pre-weld requirements such as setting

the wire feed speed dial, a pre-weld checklist, an

operating sequence (Fig. 10) and inspection during and

3.3 SETTING WIRE SPEED DIAL

after operation. As additional aids toward understand-

ing this system, a schematic diagram (Fig. 11) and

Manually set the desired wire feed speed on the dial

wiring diagram (Fig. 12) are included at the end of

of the wire feed speed dial (Fig. 3), as follows:

this section.

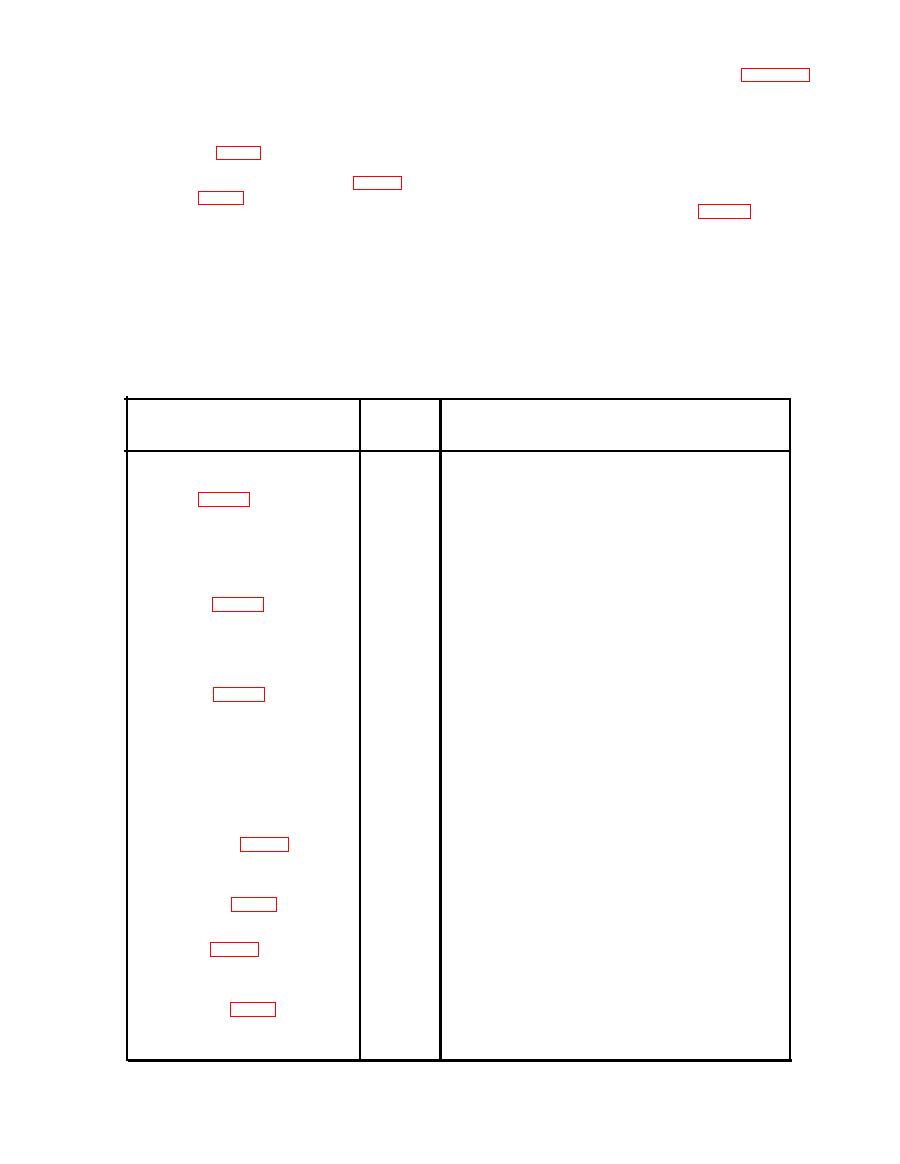

TABLE IV

Functions of Controls and Selected Electrical Components

Control or

Function

Symbol

Component

For manual setting of desired wire feed

Wire Feed Speed

Rlll

speed. Rated: 0-20, 000 ohms, 5W, con-

Potentiometer

tinuously variable.

Dial (Fig. 3)

Functions in parallel with Rlll when PUSH-

R113

PULL switch SW107 is in PULL position to

adapt Rlll for pull operation.

PUSH- PULL

PUSH position (for push guns) opens brake

SW107

Switch (Fig. 4)

solenoid circuit to apply drag on wire reel,

PULL position (for pull guns) closes brake

solenoid circuit to retract brake and remove

drag.

LOCAL position switches Wire Feed Speed

SW103

LOCAL-REMOTE

Potentiometer (Rlll) into motor control

Switch (Fig. 4)

circuit so that speed can be hand-set at

panel dial,

REMOTE position switches Rlll out of and

Remote Control (R112) into motor circuit

so that speed can be set on the remote

control.

TG101

Produces electrical equivalent of existing

motor speed for motor control circuit in

Generator (Fig. 4)

control unit.

BS101

Retracts brake during pull operation of

Solenoid:

Brake (Fig. 11)

Feeder when energized by pull gun trigger,

Upon release of trigger, brake engages.

Allows gas flow during push or pull opera-

Gas (Fig. 12)

GS101

tion of Feeder when energized by gun

trigger,

Water (Fig. 12)

Allows water to flow during push or pull

WSl0l

operation of Feeder when energized by

gun trigger.

43